Description:

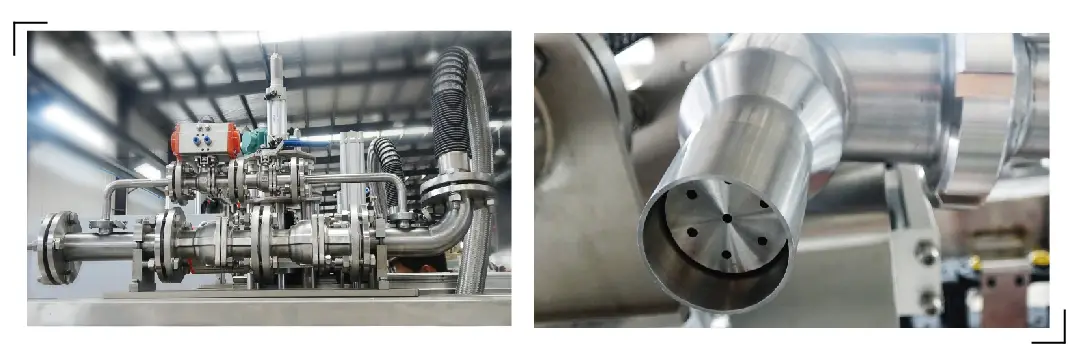

Three stations: positioning and opening-automatic filling-automatic cap opening and capping This machine is an intelligent packaging system specially designed for the packaging of liquid drums of 50-300kg. The main machine part of the filling adopts a stainless steel environmental protection frame, with a window, automatic sliding door, and a closed type during filling; the entire line automatically completes the drum. The sliding door opens and closes, automatic identification of the drum mouth, automatic alignment of the drum mouth, automatic cap opening, automatic filling, and automatic capping at the end of filling.

After the filling of each batch of materials, the remaining materials in the pipeline are purged into the filling container, and the materials in the drum will continue to be used during the second filling. The unique fixing method of the filling plug ensures that a detection switch is installed on the cylinder that controls the opening and closing of the filling head. Before the filling head is completely closed, the gun head will not be lifted out of the drum to prevent the material from being sprayed out of the drum The filling head is additionally designed with a receiving tray. After the filling is completed, the leakage tray extends to prevent the liquid from the filling head from contaminating the packaging and the conveying line. The weighing system uses high-precision weighing instruments and Toledo weighing sensors to ensure filling accuracy while increasing the stability of structure and operation. In addition, the system has anti-corrosion and anti-overload protection devices. The sensor is IP68 protection, and the sensor is easy to install, disassemble and repair. The accuracy of the weighing system is controlled by a high-precision weighing instrument, and the accuracy of a small flow can be fine-tuned.

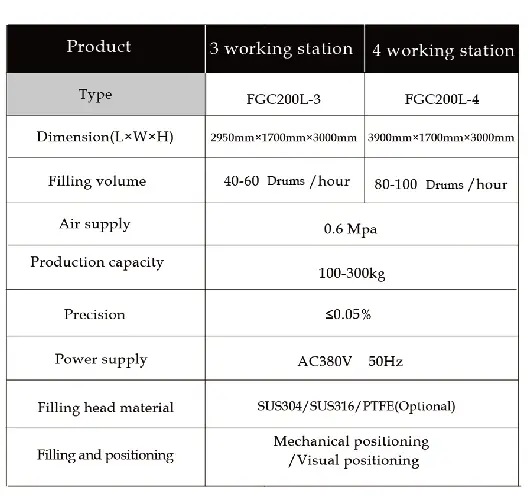

Product Details:

VIDEO:

VIDEO: